Welcome to our latest product review, where we dive into the fascinating world of CNC machinery and precision engineering. Today, we’re excited to share our firsthand experience with the RATTMMOTOR Nema34 Closed Loop Hybrid Servo Motor Stepper Motor Kit. With a muscle-bound torque rating of 12N.m (or 1700oz-in) and a robust design tailored for CNC routers, engravers, and milling machines, this motor kit promises not just power, but precision and reliability as well.

Having just put this advanced piece of technology through its paces in our workshop, we can attest to its capabilities and performance features. From its state-of-the-art closed loop system that effectively eliminates the risk of losing steps, to the impressive 32-bit DSP for enhanced control, we’ve found ourselves astounded by how it elevates our machining projects. Furthermore, the inclusion of the HSS86 servo driver and the generous 3m wire length make setup a breeze for both seasoned pros and enthusiastic DIYers alike.

Join us as we break down the specifications, explore the advantages, and ultimately share our insights on whether the RATTMMOTOR Nema34 is the powerhouse every workshop needs, or just another contender in the crowded market of stepper motors. Let’s get started!

B08HRKWCXV

After testing this hybrid servo motor and driver kit, we were impressed by its advanced features and seamless operation. The closed loop system ensures that the motor never loses steps, which is crucial for precision tasks like CNC routing and engraving. The 32-bit DSP control technology enhances accuracy while the automatic load adjustment significantly improves torque and speed capabilities. Additionally, the option for 16 types of microstepping allows for utmost flexibility, making it suitable for various machining requirements.

We also appreciated the robust safety features integrated into the system. With built-in protections for over-current, over-voltage, and positional tolerance, we felt secure in its operation. The positioning alarm output offers an added layer of monitoring, enabling proactive maintenance. This kit fits a wide range of applications, from engraving machines to industrial sewing machines. Whether dealing with heavy loads or more delicate tasks, it adapts without the need for extensive adjustments. this is a versatile solution for professionals looking to enhance their CNC projects. Explore More

B09MY7XP9L

After testing the hybrid servo motor and driver kit, we are genuinely impressed with its performance and capabilities. The closed-loop system offers significant advantages, including the ability to never lose a step, which is crucial during complex CNC tasks. Thanks to the advanced 32-bit DSP technology and vector control, the output torque and speed have shown remarkable improvement, making it suitable for various applications. One standout feature is the automatic current adjustment based on the load, which ensures that the motor operates efficiently without unnecessary strain. Coupled with its wide range of microstepping options (up to 51200 microsteps/rev), this setup provides superior precision for intricate projects.

This kit’s versatility cannot be overstated, as it is compatible with numerous devices including engraving machines, CNC routers, and even automatic assembly equipment. We appreciate the comprehensive safety features, which include over-current and over-voltage protections, along with position monitoring and alarm signals. These functions not only enhance the reliability of the system but also ensure safe operation. whether you’re milling, cutting, or engraving, this powerhouse of a motor and driver plays a pivotal role in optimizing performance across various setups.

B07411XP67

We are highly impressed with the performance of the closed-loop hybrid servo motor and driver kit. One of the standout features is its 12N.m holding torque, which ensures that we never lose steps during operation. The integration of a new generation 32-bit DSP significantly enhances motion control accuracy, while the vector control technology improves both the torque output and working speed. The automatic current adjustment based on load is another added benefit, preventing unnecessary strain on the system. The capability to choose from 16 types of microsteps, going up to a maximum of 51,200 microsteps/rev, gives us the precision needed for intricate CNC tasks.

In terms of safety and reliability, this system excels with features that include over-current protection, over-voltage protection, and position tolerance monitoring. The built-in alarm output signal is invaluable for real-time monitoring, ensuring we can promptly address any deviations in position. With dimensions of 86x86x156mm and a weight of around 14.2 pounds, it fits well into our workspace without taking up too much room. Its versatile applications make it suitable for various machines such as engraving tools, industrial sewing machines, and CNC setups. This comprehensive motor and driver kit is indeed a solid investment for anyone serious about automation. Explore this product now!

B078KV3XX2

We have been thoroughly impressed with this stepper motor and driver kit. With a holding torque of 12N.m (1700oz-in) and a rated current of 6A, it delivers exceptional performance for our CNC projects. The new generation 32-bit DSP control ensures superior accuracy, maintaining precise operation without losing steps. Its vector control technology optimizes motor output torque and speed, allowing for efficient and smooth operation. Additionally, the automatic current adjustment based on load is a game-changer, adapting to varying demands seamlessly. The motor’s performance is enhanced with a pulse response frequency of up to 200KHz and 16 types of microsteps available, making it highly versatile for diverse applications.

Our experience with the driver showcases its robust safety features such as over-current protection, over-voltage protection, and position outside the tolerance protection. The built-in alarm output signal aids in monitoring, ensuring operational safety during use. This motor and driver assembly is suitable for various applications, including engraving machines, CNC routers, and automatic assembly equipment, proving to be adaptable for different loads, including low stiffness pulley setups without needing adjustments. The compact dimensions make it easy to integrate into existing machines, enhancing our workflow significantly. Experience its benefits for yourself and get yours now!

B071VW5X2W

After installing this motor and driver kit on our CNC machine, we have witnessed a remarkable improvement in performance. The closed-loop system eliminates any issues with losing steps, which has noticeably enhanced our machining accuracy. With a holding torque of 12N.m (1700 oz-in) and a rated current of 6A, we experienced smoother operation even at higher speeds. The 32-bit DSP control technology ensures precise engagement and impressive output torque, making it a reliable choice for both mild and demanding tasks.

Moreover, the features included in this driver kit are exceptional. The over-current and over-voltage protection systems provide an added layer of safety, ensuring consistent performance without risk of damage. Additionally, the driver allows for 16 types of microstepping, with a maximum of 51,200 microsteps/rev, which significantly enhances our machine’s responsiveness. Whether we are using it for engraving or other tasks like marking or cutting, the seamless integration into various load conditions without the need for gain adjustments stands out. We highly recommend checking it out for anyone looking to optimize their CNC capabilities. Discover More

Pros & Cons

Pros & Cons of the RATTMMOTOR Nema34 Kit

In our journey to explore the world of CNC machinery, we’ve taken a close look at the RATTMMOTOR Nema34 Closed Loop Hybrid Servo Motor Kit. Below, we share the key pros and cons we’ve identified, helping you make an informed decision about this product.

| Pros | Cons |

|---|---|

| Exceptional Torque: With a holding torque of 12N.m, it effectively handles demanding tasks with ease. | Weighty Component: At over 14 pounds, this kit may require sturdy mounts and support to accommodate its heft during operation. |

| Closed Loop Control: The system ensures that it never loses steps, enhancing precision and reliability for complex tasks. | Initial Setup Complexity: For beginners, the installation may present a learning curve, particularly with wiring and configuration. |

| Advanced DSP Technology: The integration of a 32-bit DSP improves performance and responsiveness significantly. | Higher Price Point: Compared to standard stepper motors, this kit may be on the higher end of the budget spectrum. |

| Safety Features: Includes over-current, over-voltage protection, enhancing the safety of your CNC operation. | Limited Warranty Information: Potential buyers may find the lack of detailed warranty options concerning. |

| Versatile Application: Suitable for a wide array of machinery types, from CNC routers to industrial sewing machines, making it a great investment. | Bulkiness: The size may limit its use in smaller CNC setups or constrained spaces. |

Ultimately, our experience with the RATTMMOTOR Nema34 kit reflects its strengths in delivering precision and performance against some considerations around setup and usability. Taking these pros and cons into account will help us all decide if this kit is the right fit for our projects.

Q&A

Q&A Section: Unlock Precision with the RATTMMOTOR Nema34 Kit

Q1: What makes the RATTMMOTOR Nema34 Closed Loop Hybrid Servo Motor different from standard stepper motors?

A1: The RATTMMOTOR Nema34 stands out due to its closed-loop system which ensures that it never loses steps—something traditional stepper motors can struggle with under heavy loads. This kit employs advanced vector control technology and a new generation 32-bit DSP, enhancing accuracy and allowing for a high torque output. This means we can expect smooth and precise operations, especially in demanding applications like CNC machining.

Q2: What applications is this motor kit suitable for?

A2: This motor driver kit is incredibly versatile! It’s applicable for a variety of machinery, including CNC routers, engraving machines, industrial sewing machines, cutting machines, plotters, and more. We appreciate this wide range of uses because it makes integrating the system into existing setups quite convenient, regardless of the specific automation application we’re working on.

Q3: Does the kit support different microstepping options?

A3: Yes, one of the notable features of this kit is that it offers 16 microstep options, with the capability to achieve up to 51,200 microsteps per revolution. This flexibility allows us to fine-tune performance to perfectly suit the precision requirements of our projects. Whether working on intricate details or sharper movements, we can select the microstepping that best fits our needs.

Q4: How easy is it to set up the RATTMMOTOR Nema34 kit?

A4: From our experience, setup is relatively straightforward. The kit comes with everything necessary for installation, and the wiring is well-marked and organized. While a basic understanding of electronics and CNC systems is beneficial, we found the user manual clear and helpful in guiding us through the installation process. That said, as with any complex system, a little patience goes a long way!

Q5: Is the motor kit safe to use? What safety features does it have?

A5: Absolutely! The RATTMMOTOR Nema34 kit is designed with several safety features. It includes over-current protection, over-voltage protection, and a position tolerance alarm. These features work together to protect both the motor and the connected machinery from potential damage. We appreciate these built-in safeguards, as they significantly enhance reliability during operation.

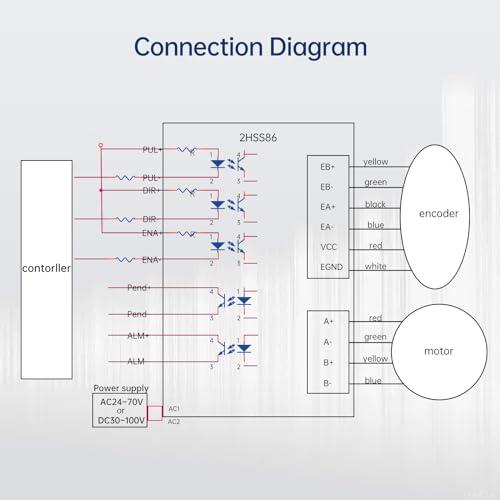

Q6: What voltage input is required for the driver unit?

A6: The driver unit supports an input voltage range of anywhere from AC 24-70V or DC 30-100V. This versatility makes it easier for us to incorporate the kit into different setups since we can often find a compatible power source without the need for additional converters.

Q7: Can this kit handle heavier loads, and how does it adjust?

A7: Yes, the RATTMMOTOR Nema34 kit is designed to manage various machine load conditions, including those with lower stiffness and pulley systems. The automatic current adjustment based on load is particularly impressive, as it optimally adjusts the current according to the demands of the operation, making it efficient and reducing the chance of overheating or stalling.

Q8: How does this motor contribute to overall machine performance?

A8: With its high holding torque of 12N.m and peak current capability of 8A, this motor significantly enhances machine performance. The closed-loop system not only prevents lost steps but also improves the motor’s output torque and working speed. Consequently, we experienced smoother operations and quicker setups, which ultimately leads to higher productivity in our CNC projects.

With the RATTMMOTOR Nema34 kit, we feel empowered to take on a variety of projects with confidence. Whether you’re a hobbyist or a seasoned professional, we believe this kit is a game-changer that will elevate your CNC machining experience.

Ignite Your Passion

As we conclude our exploration of the RATTMMOTOR Nema34 Closed Loop Hybrid Servo Motor Kit, we are left with an appreciation for its impressive capabilities and robust design. This powerhouse of a motor not only provides unparalleled precision but also enhances the overall efficiency of our CNC projects. With features like automatic current adjustment and a cutting-edge DSP control, we believe this kit is a worthy investment for anyone looking to elevate their machining experience.

Whether you’re involved in engraving, cutting, or any small automated task, the RATTMMOTOR kit has proven to adapt seamlessly to various applications, making it versatile and dependable. We’ve only scratched the surface of its capabilities, and we can’t wait to see how it continues to impress in our future projects.

If you’re ready to unlock precision in your CNC endeavors, we highly recommend checking out the RATTMMOTOR Nema34 Kit. Experience its brilliance for yourself by visiting the link below:

Reviews

There are no reviews yet.