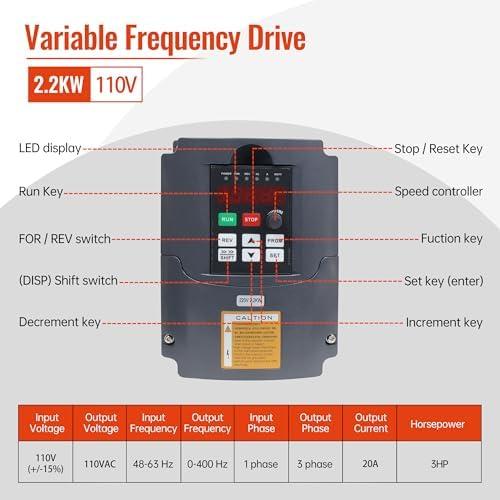

Welcome back to our blog, where we dive deep into the world of tools and technologies that enhance our projects! Today, we’re excited to share our hands-on experience with the RATTMMOTOR Variable Frequency Drive 2.2KW 110V VFD Drive Inverter. Designed to provide precise speed control for both water-cooled and air-cooled spindle motors, this powerful device allows us to unlock the full potential of our machinery in a way that feels both professional and user-friendly.

From the moment we unboxed this VFD drive inverter, we could see that RATTMMOTOR has packed a wealth of features into a compact unit. With multiple control options, robust protection mechanisms, and a clear user interface, we were eager to set it up and put it to the test in various applications.

In this review, we will cover not only the technical specifications but also our practical insights from using the inverter in real-world scenarios. Whether you’re a hobbyist or a professional looking to elevate your workshop’s capabilities, our experience with the RATTMMOTOR VFD might just guide you in the right direction. So, let’s dive in and explore what makes this product stand out in the realm of frequency drives!

B08HRKWCXV

We have been thoroughly impressed with the capabilities of this frequency drive. It allows for flexible control with features such as a selectable V/F curve, four segment reduction time, and a significant starting torque that can reach up to 150%. The multi-function input terminals enable us to control speed easily, execute program operations, and respond to external emergency stop functions. Additionally, the display provides clear information regarding frequency, current, voltage, and running status, making it a user-friendly device suitable for various applications.

Safety has also been a priority with this unit, offering a range of protection functions. From overload protection to electronic circuit safeguards, it ensures smooth operation under various conditions. The ability to install the unit vertically to facilitate better cooling performance is a notable design feature. We appreciate the clear manual instructions that assisted us in installation and safe usage, maximizing the inverter’s functionality. For those looking to enhance their motor control capabilities, this drive comes highly recommended for performance and reliability.

| Feature | Description |

|---|---|

| Power | 2.2KW |

| Input Voltage | 1 or 3 phase 110V |

| Output Voltage | 3 phase 110V |

| Temperature Range | -10 to 40℃ |

B09MY7XP9L

The performance of this variable frequency drive has exceeded our expectations, especially with its multi-functionality that supports extensive speed control options. We were impressed by the flexibility it offers with the 4 segment reduction time selection ranging from 0.1 to 6500 seconds, allowing us to customize the functionality according to our needs. Setting different V/F curves and torque adjustments was straightforward, and the automatic voltage regulation feature added an extra layer of reliability. Additionally, the multi-protection functions such as overload protection and anti-stall mechanisms ensured that our operations ran smoothly without unnecessary interruptions.

Installation was uncomplicated, provided we adhered to the guidelines in the manual. The requirement for vertical installation to enhance cooling has proven effective, as we noted a significant drop in overheating incidents compared to previous setups. The detailed display relays essential information such as voltage and frequency, which aids us in monitoring performance at a glance. With its robust design and user-friendly features, we feel confident about the durability and dependability of this product for our spindle motor applications. For those looking to enhance their setup, we highly recommend taking a closer look at it on Amazon. Check it out here!

B07411XP67

Product Review:

The variable frequency drive we explored has proven to be a robust tool for managing spindle motor speed. With features such as 4 segment reduction time settings ranging from 0.1 to 6500 seconds, it’s easily adjustable and can cater to a variety of applications. The ability to set both a V/F curve and torque values, with a starting torque reaching up to 150%, greatly enhances its utility. Additionally, the integrated automatic voltage regulator (AVR), deceleration stop, and DC brake functionalities provide essential control and safety measures, making it a versatile choice for different operational requirements.

Moreover, the multi-function input and output terminals enable complex configurations, supporting up to 8 speed controls and offering real-time feedback on parameters like running status and faults. The security features are comprehensive as well, with protections against overload, voltage fluctuations, and over-temperature, ensuring reliability in operation. To maximize performance, it’s crucial to install the unit in a well-ventilated space, ideally in a vertical position. Users will benefit significantly from understanding the installation manual to exploit the product’s full potential. Check it out here!

B078KV3XX2

We have found this variable frequency drive to be an impressive solution for those needing precise control over spindle motor speeds. The ability to adjust the V/F curve and torque settings allows for fine-tuning performance across various applications. We particularly appreciate the multi-function input terminals, which enable features such as 8-speed control and external emergency stops. Furthermore, with the automatic voltage regulator and multiple protection functions, it offers a robust and reliable operation, ensuring safety and efficiency while running our equipment.

Installation has proven to be straightforward, especially with the instruction manual included in the package. By ensuring proper ventilation during installation, we maximized the cooling effect, which is critical for maintaining performance. The operational temperature range and communication control via RS-485 add layers of flexibility that enhance our overall workflow. Here’s a quick overview of its specifications:

| Specification | Details |

|---|---|

| Power | 2.2KW |

| Input Phase | 1 or 3 phase 110V |

| Output Frequency | 3 phase 110V 0-400Hz |

| Cooling | Vertical installation required |

We believe this product could greatly enhance your operations and provide consistent performance for various applications. Explore more about its features and see if it meets your needs by visiting this link.

B071VW5X2W

In using the variable frequency drive, we were pleasantly surprised by its versatility and array of features. The ability to select from four segment reduction times, along with customizable V/F curves and torque settings, allows us to tailor the drive’s functionality to our specific needs. We appreciate the automatic voltage regulation and various protective measures such as overload protection and anti-stall features, which enhance safety while operating. The technical parameters, including its ability to handle inputs from single or three-phase power, make it suitable for various applications, whether for air-cooled or water-cooled spindle motors.

Installation was straightforward, thanks to the clear manual included in the package. We found the multi-function input and output terminals incredibly beneficial for achieving multiple speed control options and monitoring outputs such as speed and temperature. The display is user-friendly, showing real-time information that aids in adjustments and troubleshooting. the drive’s solid construction and reliability under different operational conditions convinced us that it was a valuable addition to our equipment lineup. For those looking for an effective solution for spindle motor speed control, we recommend checking this product out. Explore on Amazon

Pros & Cons

Pros & Cons of the RATTMMOTOR VFD Inverter

As we dive deeper into the capabilities of the RATTMMOTOR Variable Frequency Drive, it’s important to highlight its strengths and weaknesses. This will help us make an informed decision about whether it truly meets our needs. Here’s what we found:

| Pros | Cons |

|---|---|

|

|

the RATTMMOTOR VFD Inverter offers a solid mix of power, functionality, and protection, but potential users should weigh these pros and cons against their unique requirements and experience levels.

Q&A

Q&A Section: Unlocking Precision – Our Review of RATTMMOTOR VFD Inverter

Q1: What is the RATTMMOTOR VFD Inverter mainly used for?

A1: The RATTMMOTOR VFD Inverter is designed to control the speed and torque of three-phase motors, making it ideal for applications such as water-cooled and air-cooled spindle motors. It’s particularly useful in machinery and equipment requiring variable speed control.

Q2: How easy is it to install the RATTMMOTOR VFD?

A2: Installing the VFD is straightforward, provided you follow the included instruction manual. It’s crucial to install the inverter vertically to ensure optimal cooling and air circulation. We recommend taking your time to familiarize yourself with the installation instructions for the best results.

Q3: What type of input power does this inverter accept?

A3: This inverter can accept single-phase or three-phase input at 110V, operating on either 50Hz or 60Hz. This versatility allows it to fit into various setups and applications.

Q4: Can this inverter help improve energy efficiency?

A4: Yes, the VFD inverter allows better control over the motor’s speed, leading to significant energy savings, particularly in applications where the load doesn’t always require full power. By adjusting the speed to match the demand, the inverter helps to reduce unnecessary energy consumption.

Q5: What safety features are included in this inverter?

A5: The RATTMMOTOR VFD Inverter is equipped with several protective measures, including overload protection, over-voltage and low-voltage protection, and a fuse broken-motor stops protection system. These features contribute to safer operation and extend the lifespan of both the inverter and the connected motor.

Q6: How does the VFD enhance motor performance?

A6: The inverter provides precise control over motor speed and torque settings. It offers functions like adjustable V/F curves, automatic voltage regulation (AVR), and flexible start torque configurations. These features optimize motor performance for various tasks, whether it’s ramping up speed gradually or maintaining consistent torque under load.

Q7: Are there any specific maintenance requirements for the VFD?

A7: Regular maintenance is minimal, but it’s important to keep the inverter clean and ensure proper airflow around the unit. Checking connections periodically and ensuring that the installation complies with the guidelines in the manual will help maintain its performance and longevity.

Q8: Can the RATTMMOTOR VFD be used with a PLC?

A8: Absolutely! The inverter is compatible with PLC program control, allowing for more complex automation setups. This feature allows users to integrate the VFD within larger control systems for enhanced functionality.

Q9: What kind of feedback can the inverter provide during operation?

A9: The RATTMMOTOR VFD comes with a five-digit display and status indicator lights that show critical information like frequency, current, voltage, motor speed, and fault warnings. This real-time feedback aids in monitoring system performance and troubleshooting potential issues.

Q10: Is there an extension cable included with the product?

A10: Yes, the RATTMMOTOR VFD Inverter package includes a VFD extension cable, which facilitates easy connections and ensures you can set up your equipment with convenience.

We hope this Q&A helps clarify any doubts you may have about the RATTMMOTOR VFD Inverter! If you have more questions, feel free to reach out, and we’ll be happy to assist further.

Transform Your World

As we wrap up our exploration of the RATTMMOTOR Variable Frequency Drive, it’s clear that this VFD inverter packs a powerful punch when it comes to precision control for spindle motors. The versatility it offers, from customizable speed settings to a plethora of protection features, sets it apart as a reliable choice for both amateur and professional use. Its ease of installation and robust performance are sure to meet the demands of various machining tasks, enhancing overall efficiency in the workshop.

For those seeking to optimize their spindle motor operations and elevate their projects to new heights, the RATTMMOTOR VFD Inverter stands as a strong contender. We encourage you to dive into the feedback from users who have found success with this product and see for yourself the difference it can make.

Ready to take the next step in precise motor control? Discover the RATTMMOTOR Variable Frequency Drive here, and unlock the precision you’ve been waiting for!

Reviews

There are no reviews yet.